When we bought Delancey in 2006, one of the big selling points was that she had davits, cranes for hoisting a dinghy, on her stern. This would allow us to cruise without having to tow or hoist a dinghy up onto the deck. Not only did she have davits, but she also came with a dinghy to hang from them! And not just any dinghy, but a hard-bottomed inflatable. The hard bottom would allow us (with the motor) to get her up on a plane and skim across the water's surface. This was going to be a big improvement over our old dink, with its soft, non-hydrodynamic bottom and Peter-powered oars.

But it was old. It's a 1999 Zeppelin, sold under the name "Bear". It had proprietary oarlocks but no matching oars. The tubes were faded and chalky. It didn't hold air very long. After a few seasons I started to imagine how I could improve the dink. I began looking at dinghies I liked and it hit me that I could order my favorite bits from different manufacturers and create my perfect Frankendink!

After some digging, I was able to get combination handles/cleats on Carib inflatables, universal oarlocks from AB, an Achilles rubrail, and some other bits. Now I was set, but she still didn't hold air very well. I would have to patch any leaks and do something about the valves.

This project was clearly too big and messy to do on the dock. Deb's folks kindly let us take a corner of their backyard for a few weeks. So we deflated and jammed the dink into the truck and drove out to New Jersey.

First was the valves. I was given a lot of guidance by good folks at NRS. From them I bought replacement valves as well as hypalon donught patches to seat them. Step one, unscrew the old valves. I did it with one hand holding the inner bit through the fabric and a large wrench on the outer ring.

Next I cut slits into the fabric to remove the old inner valve piece.

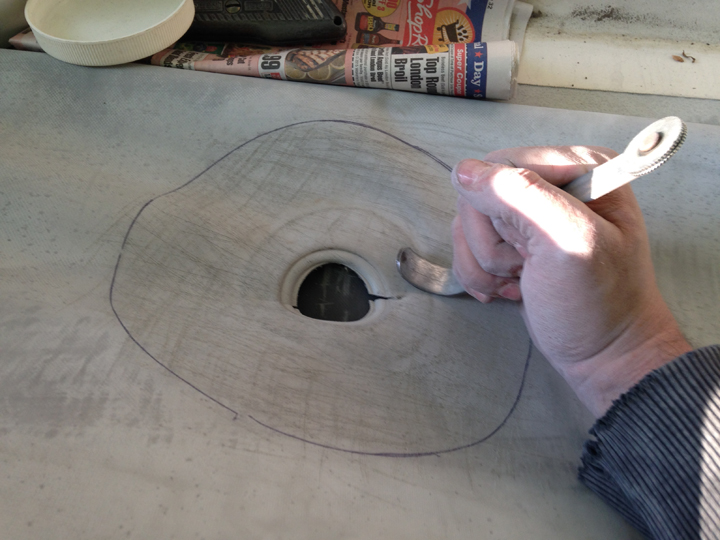

Then, after inserting the interior half of the new valve into the hole, I roughened up and applied cement to both surfaces of the doughnut patch. The instructions call for multiple applications of cement with time to dry before mating the surfaces.

The new valves screw together like the old ones came apart, only without the wrench. When the first patch was done, I did it again, and again, and again.

Here she is, after the first weekend with all her hardware and patches. I had previously glued on the handles and rubrail, but the glue had failed around the edges over the years (read and follow your cement instructions folks!), so I added beads of 3M 5200 adhesive sealant around their perimeters.

One week later and she's holding air! Awesome! I also realized that I glued the oarlocks on backwards. Oh well.

I used paint by Marine Development and Research, on the strength of a good review in Practical Sailor. MDR also sold me their Amazon's Inflatable Boat Cleaner to prep the tubes. The bottle says to just spray it on and rinse it off, no scrubbing required. It worked exactly as advertised.

The paint went on smoothly. I applied one coat, had lunch, and applied the second coat.

I got all fancy with the finishing touches. I painted the rubrail and the name in a darker gray. I cut the name stencil from drafting mylar. We named the dink Les for "LES", or Lower East Side, our old land home and the neighborhood through which Delancey Street runs. Now you know.

And we're done! Now to get her back to out of my in-law's garage and back to our Jersey City marina.

There's no way we were going to jam this thing inside our truck for the way home. Instead I rented a Ford F250 truck from Home Depot for one hour. Made our Land Rover feel like a Miata.

Back on the dock, I slipped her into the water. I even remembered to insert the stern plug first.

Good as new! This project had been hanging over me, started but never finished, for about seven years. I'm super happy that it's done and how well it turned out. We won't talk about what it took to get the outboard started.

Okay! What's next?